- Description

-

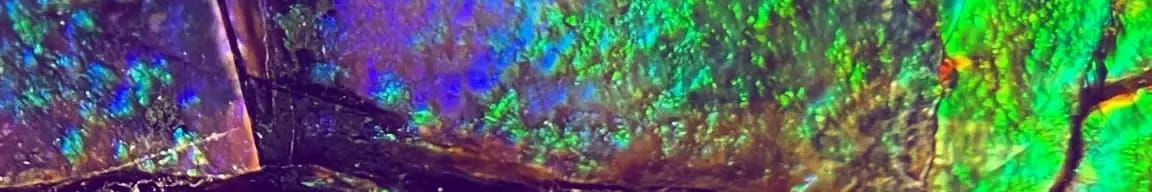

Lucentara represents an innovative fusion of scientific technology and luxury, seamlessly integrating advanced research, gemstone technology, and precision restoration. Specializing in the transformative potential of ammolite, Lucentara serves as a hub for groundbreaking applications—from advanced optical security solutions and microchip development to sophisticated material encoding. Here, the ancient allure of Earth's rarest treasures meets cutting-edge scientific craftsmanship, offering discerning clientele and technology investors unparalleled access to pioneering ammolite innovations.

- Number of employees

- 2 - 10 employees

- Company website

- https://www.dinostyfossils.ca

- Categories

- Competitive analysis Market research Product or service launch Project management Sales strategy

- Industries

- Retail Sales Science Trade & international business

- Representation

- Family-Owned Indigenous-Owned Neurodivergent-Owned Small Business Women-Owned

Socials

Recent projects

Ammonite Fossil Restoration System

The project aims to develop a precision system for patching and fitting ammonite fossils found in Southern Alberta. These fossils, known for their intricate patterns and historical significance, require meticulous restoration to preserve their integrity. The goal is to create a user-friendly system that allows for accurate alignment and fitting of fossil fragments, ensuring minimal damage and maximum preservation. The project will involve researching existing restoration techniques, designing a prototype system, and testing its effectiveness on sample fossils. This project provides learners with the opportunity to apply their knowledge of paleontology, materials science, and engineering principles to a real-world problem. The tasks are closely related and can be completed by a team of learners from a paleontology or related program. 1. Scan the fossil surface Detect and measure irregular patch areas directly from high-resolution images or 3D scans. 2. Digitally outline missing sections Automatically generate precise vector outlines of the gaps to be filled. 3. Output a cut template Convert outlines into cut paths for a laser cutter, CNC, or vinyl cutter to create physical stencils or directly cut gem/backing material. 4. Ensure tight tolerance fit Adjust the outlines to account for kerf, grinding allowance, and epoxy fill, producing multiple fit variants (tight, snug, roomy).

AI-Enhanced Fossil Identification and Efficiency Optimization

LUCENTARA / Dinosty Fossils is seeking to enhance its fossil detection capabilities and streamline its excavation processes through the integration of artificial intelligence. The primary challenge is to develop a strategy that leverages AI to accurately identify fossils within excavation sites while simultaneously reducing the amount of overburden—unnecessary material that must be removed to access fossils. This project aims to apply machine learning techniques to analyze geological data and improve the precision of fossil detection. By doing so, the company hopes to increase operational efficiency and reduce costs associated with manual labor and material handling. The project will involve creating a prototype AI model that can be tested and refined based on real-world data provided by LUCENTARA / Dinosty Fossils. Key tasks include: - Researching existing AI models applicable to geological data analysis. - Developing a prototype AI model for fossil detection. - Testing the model with sample data to evaluate its accuracy and efficiency. - Proposing strategies for integrating the AI model into existing workflows.

AI-Driven Quality Control System for Ammolite Clear Coat Finishing

Lucentara / Dinosty Fossils specializes in preparing and finishing ammolite gemstones and fossils. A key production step is spraying a 2-component (2K) clear coat to protect and enhance the optical properties of the stone. One of the biggest issues is ensuring full coverage — pinholes and micro-bubbles can form if spray passes are uneven or if substrate conditions vary. These defects reduce yield and increase rework costs. Develop a prototype quality control system that can detect, predict, or prevent pinholes and bubbles during or immediately after spraying clear coat on ammolite specimens.

Precision Laser Fossil Preparation

The project involves the meticulous removal of concretion surrounding an ammonite fossil from Southern Alberta using a fiber laser. The goal is to expose the fossil without causing any damage to its delicate structure. This task requires precision and an understanding of both fossil preservation and laser technology. The project will provide learners with the opportunity to apply their knowledge of laser physics and paleontology. The team will need to develop a methodical approach to calibrate the laser settings for optimal precision. Additionally, they will document the process, noting any challenges and solutions encountered. This project aims to enhance learners' skills in precision work and interdisciplinary application of classroom knowledge.